Interaction of beryllium with hydrogen plasma - nuclear fusion first wall investigations

Beryllium is one of the most promising candidates as material for

the first wall of future nuclear fusion devices. However, the

processes that take place on the wall surface in such an

environment are not fully investigated yet.

We are concentrating on the question whether an oxide layer will

develop on the beryllium surface under these conditions and if so,

how it influences the interaction with the plasma, especially the

retention of hydrogen in the bulk.

Previous work

The first step in this project was the determination of the

oxidation kinetics of beryllium in air. This consisted of

determining the thickness of the oxide layer of beryllium samples

that were heated for durations between 1 and 50 hours at

temperatures up to 600 °C.

The samples were heated in our tubular furnace, measurement of the

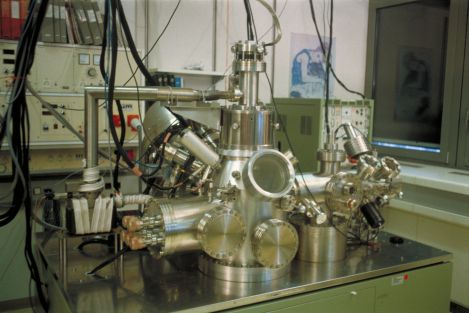

oxide layer thickness was done by sputter depth profiling in our

Auger spectrometer. For this purpose, a fine polished sample

surface is needed. As beryllium dust is highly toxic, we set up a

glove box with a polishing machine including a closed water circuit

for wet polishing.

According to our results, the oxide growth of beryllium in air

follows a square root law, as is expected for diffusion limited

oxidation, with an activation energy of 1,16 eV.

Need caption.

Current investigations

We attached a hydrogen supply and an R.F. plasma generator to the

tubular furnace to simulate the conditions in the plasma edge

region of a fusion reactor (which is possible only to a certain

degree). The first heating cycles (up to 400 °C) in hydrogen

plasma showed that previously thick oxide layers are reduced by a

certain amount, but oxygen-containing impurities in the furnace

(water vapour) cause previously thin oxide layers to grow,

resulting in a constant medium oxide thickness for all samples at

the end of these experiments.

The next important step will be to establish a relation between the

amount of impurities in the furnace and the final oxide thickness.

After that, the amount of hydrogen that the beryllium samples take

up during these plasma treatments will be measured by outgasing

experiments. The final goal (for the time being) is to find a

dependence of this hydrogen retention on the thickness of the oxide

layer that develops during plasma exposure.